Colour Coding of Pattern In the Casting Process

|

| Colour Coding of Pattern In Casting |

Why colour coding of patterns is required in casting?

To get the best result from the pattern, the pattern maker needs to mark the pattern with a different colour to indicate the exact function of every part of the pattern by colouring the pattern.

Patterns are coloured to provide visualization of the machined surface and identification of the main body.

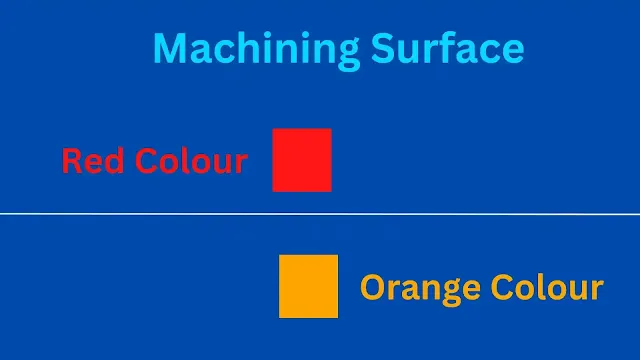

The surface to be machined is given the colour red as the colour code as shown in the diagram below (a) below.

Core prints and seats are given the colour yellow as the colour code on the pattern as shown below in diagram (b).

The loose piece or loose core prints on the pattern are given the colour yellow/red diagonal strips as shown in diagram (c).

|

| (c) Loose Pieces Of Pattern Colour Code |

Stop-offs are given yellow/black diagonal strips as shown below in diagram (d).

|

| (d) Stop Off Diagonal Colour Code |

The surface to be cast or unmachined surface is given a black colour as shown below in diagram (e).

A black strip diagonal is used to strengthen the weak pattern or shorten a casting as shown in diagram (f) below.

BIS Colour Coding of Pattern

| Pattern | Pattern Colour Code |

|---|---|

| 1) Machined surface. | Red colour or Orange. |

| 2) Core prints and seats. | Yellow colour. |

| 3) Loose pieces or loose core prints. | Red strips or Yellow strips colour or Green colour. |

| 4) Stop off-diagonal. | Black strips on the yellow base. |

| 5) Core Prints on the unmachined surface. | Black colour. |

| 6) Pattern with parting surface. | No colour on the pattern surface. |

Colour Coding of Pattern

Question: The surface to be machined is marked on the pattern by what colour code?

Answer: The surface to be machined is marked on the pattern in red colour code.

Question: Which colour code is given to an unmachined pattern in the foundry?

Answer: Black colour is the code given to the pattern which is left unmachined.

Question: Which colour is given to the stop-off or support?

Answer: Black strip on a yellow background is given to the stop-off.

Question: What colour code is given to the core prints that are used to support the cores in the sand casting process?

Answer: Yellow colour code is given to the core print that is used to support the cores.

Question: When a pattern does not have a colour code on it what does it mean?

Answer: When a pattern does not have colour it means that the section of the pattern is of a parting surface.

Summary of Colour Coding In Pattern

Colour coding pattern is an important step in pattern making process for producing sand casting in the sand moulding process.

Colour codes are employed on the pattern to have a virtual view of the pattern and identify the surface to be machined, unmachined, surface that is to be kept untouched for parting surfaces, surfaces that are colour-coded for core prints & stop off and colour codes for the patterns that are to be kept loose.

Colour coding identifies the main functional sections of the pattern from the non-functional section.

Pattern colour indicates exactly the function of that particular part of the pattern adding a visual element to the pattern maker while making the pattern.