Core Box In Casting

|

| Core Box In Sand Casting |

Core box has a parting line. A core is divided into two parts. The upper part of the core box is cope and the lower part of the core box is called a drag.

Core boxes are made from wood, plastic and metal.

Metal core boxes have higher durability and are resistant to changes in the dimensions of wooden material due to moisture.

Plastic cores are used for making complex cores in the sand-casting process.

Wooden core boxes are of low cost, economical and used for small batch production of cores.

Core boxes in sand casting are used for making core. The process of core making in foundry using core has been explained in this article.

I have explained below the types of core boxes that are used for manufacturing cores.

Core Box Type

- Dump box.

- Half box.

- Split box.

- Right-hand box

- Left-hand box.

- Core box with loose pieces.

- Stricle box.

- Gang box.

- Skeleton box.

- Sweep box.

Dump Box

If cores are to be made in the shape of a slab or rectangle shape dump boxes are used for making sand cores.

Sand cores made in the dump box are not pasted together but are directly used.

Sand is rammed on in the core box creating a slab or rectangle-shaped core as shown below in diagram (b).

Half Box

Half boxes are used to make half-core at one time. To make the complete core remaining core is made and pasted (assembled) together to make one core.

Only symmetrical sand cores are made using the half box.

As shown below in diagram (c) core is made from half box in the foundry.

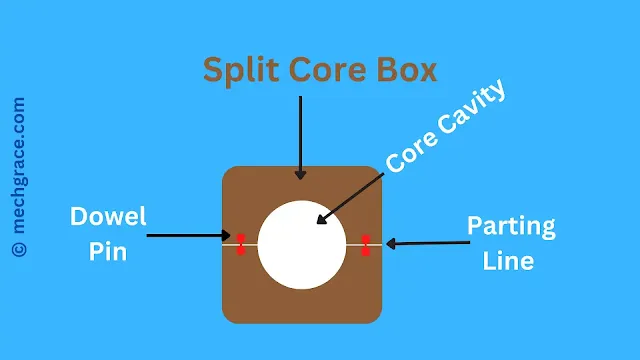

Split Box

The split box is an improvised version of the half box.

Half box makes only one side of the core but in a split box, we can make a complete core at one time.

The split box is split. Sand is rammed in the box cavity. The split box is closed and both sides are assembled together with dowel pins and an entire core is allowed to form.

Once this happens core is taken out of the core box.

A split core box is similar to a book-type core box where the box is opened and closed like a book to make a complete core.

As shown below in diagram (d), a split box is joined together using dowel pins.

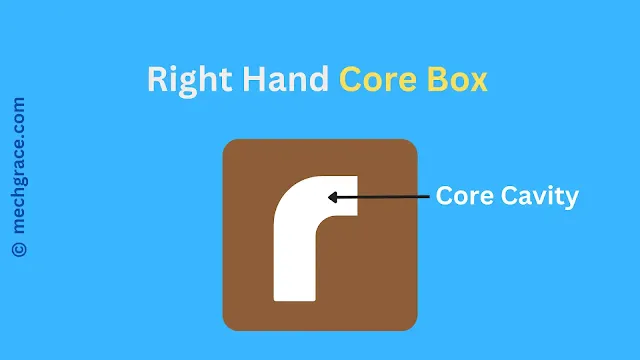

Right-hand Box

The right-hand core box is used to make the core which is to be used on the right-hand side but cannot be made in the form of a complete core and pasted together.

Shown below is the right-hand box in the diagram (e).

Left-hand Box

The left-hand core box is used to make the sand core which is to be used on the left-hand side but cannot be made in the form of a complete core and pasted together.

Shown below is the left-hand box in the diagram (f).

Stricle Box

Irregular shape cores are produced using a strickle box.

Sand is poured into the rectangular box and strickle (given shape) using a strickle board.

As shown below in diagram (g) strickle board gives shape to the required core.

Gang Box

A gang box is used to make cores in larger quantities.

Ganf box produces desirable cores in large volumes in a foundry.

Shown below in diagram (h) gang box used for the mass production of cores.

Skeleton Box

The skeleton box makes cores which are symmetrical in nature but in large size.

Core quantities made from skeleton boxes are less.

Sweep Box

A sweep box is used to make patterns by sweeping sand and making cores in larger sizes but small quantities.