Loose Piece Pattern Introduction

|

| Loose Piece Pattern In Casting |

Patterns such as cope & drag patterns, split-piece patterns, single-piece patterns, and match plate patterns can be easily withdrawn from the moulding box without any difficulty or damage to the mould.

But when the design of the pattern gets complicated the pattern cannot be withdrawn from the mould without damaging the mould cavity loose pieces of patterns are used in the sand casting process.

Loose piece patterns are made with one or more loose pieces for easy removal of the pattern from the mould boxes.

Part of the pattern that causes obstruction while pattern removal is made a loose piece. This loose piece is detached while removing the pattern from the mould in pieces.

There can be more than one loose piece in a loose-piece pattern. These patterns are attached together with dowel pins in the dovetail slot and wires before the sand ramming operation.

Lightweight wood is preferred to be used as a patterned material for making loose piece patterns.

I have written a detailed article below for students explaining loose piece patterns with diagrams, applications, advantages, disadvantages and MCQ (Multiple choice question related to loose piece patterns).

{tocify} $title={Loose Piece Pattern Table of Content }

Loose Piece Pattern

What is a loose piece pattern in casting?

A loose piece pattern is used where the pattern cannot be taken out in one piece from the sand. This pattern is used when the design of the pattern is projecting, overhanging and undercutting.

This pattern is designed in such a way that the pattern can be easily withdrawn from the sand without disturbing the mould cavity.

In order to achieve this pattern is made separately, assembled together with pins and withdrawn in loose pieces from the sand as explained below.

First, the main part of the pattern is removed followed by the loose piece or pieces.

A loose piece pattern is placed in the sand to make a mould cavity as shown below in diagram (a).

|

| (a) Loose Piece Pattern Diagram |

If we remove the above pattern directly mould cavity will be disturbed. So we removed the loose pattern in series to avoid damage to the mould cavity.

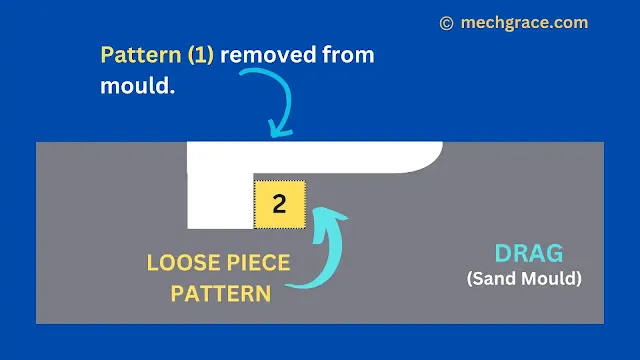

As shown in diagram (b) below pattern (1) is removed from the mould first leaving the mould impression behind.

|

| (b) Loose Piece Pattern In Sand Casting |

Now we remove the loose piece of pattern (2) from the mould successfully without damaging the mould as shown in diagram (c) below.

|

| (c) Loose Pattern Removed From Mould |

Now we have a desirable mould cavity as shown in diagram (c) above.

Molten metal is poured into the mould cavity as shown in diagram (d) below.

|

| (d) Molten Metal Poured In Cavity Made From Loose Piece Pattern |

Once the metal is solidified in the sand mould we get complex casting that cannot be produced by single piece pattern as shown in diagram (e) below.

|

| (e) Loose Piece Pattern Casting |

How are loose pieces attached to make one pattern?

Loose-piece patterns are held with wire, pin and dovetail slide.

First, the main pattern is removed from the sand followed by a loose piece of the pattern.

This kind of pattern is made where the casting requirement is such that the pattern is in two planes and the pattern cannot be taken out in a single piece.

While designing a pattern care must be taken to design the pattern keeping in mind the parting line.

What material is used for making loose piece patterns?

The best material for making loose-piece patterns is wood.

Metal is not a suitable material for this pattern because wood is easy to assemble with wire, pin or dovetail slide and withdrawing the wood pattern is easy as compared to metal pieces.

What steps are used to make a sand casting using loose piece patterns in casting?

To make the casting following steps are carried out to make sand casting:

- Step 1 - The pattern is kept on board, sand is poured on the pattern and sand is rammed.

- Step 2 - After this pattern is taken out of the mould box in pieces one after the other.

- Step 3 - After the pattern is taken out, molten metal is poured to make sand casting in the cavity made by a loose piece pattern.

In how many casting processes loose piece pattern is used?

Loose piece patterns are used in the following casting process.

- Sand casting process to make a sand casting.

- Investment casting to make wax patterns.

- Shell casting to make plastic and metal patterns.

Loose Piece Pattern Advantages

- Overhanging complex shape casting that cannot be produced by a single-piece pattern, match plate pattern, split-piece pattern, multi-piece pattern and cope & drag pattern can be produced.

- The design flexibility of loose piece patterns is high making an intricate casting as individual loose patterns can be made separately.

- The entire pattern need not be replaced if a single piece of the pattern is worn out.

- The accuracy of the pattern is high as there is the flexibility of designing and producing patterns separately.

- Patterns can be designed in such a way that it reduces pattern material waste.

- Best for application of the product with varying wall sectional thickness.

- As patterns are made separately and assembled together to produce final casting replacement of worn-out pattern pieces can be easily done.

Loose Piece Pattern Disadvantages

- The time-consuming process to take time to remove loose pieces from the mould box.

- Two or more pieces need to be produced for a loose-piece pattern.

- Pattern-making is a more complex process than other patterns such as single, split, match plate and multi-piece patterns.

- Skilled labour is required to produce more than one pattern, assemble them together, do sand ramming operations and withdraw from the mould without disturbing the mould impression.

- Loose piece patterns are more expensive to produce than split, solid and cope and drag patterns.

- The pattern can shift its position when sand is not properly rammed.

- Metal pattern is not preferred for making pattern because of weight and difficulty in pattern assembly.

- Care must be taken to avoid misalignment, fitment and mismatch of the pattern.

- High-volume production is not possible as a pattern withdrawal process depends upon the skill of the operator.

- The number of operators required is more increasing the labour cost as compared to other patterns.

- Wood is the best material for loose piece patterns in casting as it is light in weight, easy to withdraw from the mould and can be seamlessly assembled.

Loose Piece Pattern Application

Examples and products that are manufactured using loose piece patterns are as follows:

- Industrial furnace components.

- Machine components.

- Turbine components.

- Air lock valve.

- Axile pin for axels.

- Compressor blades.

- Complex compressor housing.

- Axel pins.

- Flanges.

- Starter frame.

- Aircraft engine parts.

- Gib blocks.

- Rotor hub assembly.

Loose Piece Pattern In Casting MCQ (Multiple Choice Question & Answers) / Practice Questions

1) Which of the following pattern is withdrawn from the mould in parts to avoid damage to the mould cavity?

2) Loose pieces of the pattern are assembled together using which of the following methods?

3) Patterns having loose pieces are colour-coded with what colour?

4) Loose piece patterns can be totally eliminated by using which of the following methods?

5) Which of the following pattern can produce overhanging and projection-based casting that are cast along the parting line in both the cope and drag side of the mould?

Loose Piece Pattern In Casting Summary

The loose piece pattern in casting is one of the patterns among 17 types of pattern in casting.

Pattern design is different from the split piece pattern for designing complex shapes and producing detailed sand casting.

Dowel pins and wires are used to assemble the pattern with tight dimensional tolerances.

This pattern is called a loose-piece pattern because pattern pieces are not permanently attached together. Instead, pattern pieces are "loosely" assembled to the main pattern body so they can be withdrawn without any obstruction.

Loose pieces of the pattern are produced separately, assembled and disassembled to make a complex shape casting.

This pattern ensures that there is no damage to the mould when the pattern is lifted/withdrawn by the operator and is used when the pattern is divided above and below the parting line.

Complex patterns that cannot be produced using single piece pattern are produced using a loose-piece pattern in a foundry.

Where it is not possible to use loose-piece wooden patterns, single-piece pattern with foam material is used.

Loose pieces in loose-piece patterns can be avoided by using an outer core.