Single Piece Pattern Introduction

|

| (a) Single Piece Pattern In Casting |

In the manufacturing industry, there is a need to produce casting with simple designs smaller in size for prototype purposes.

This casting can be made in less time with a solid piece pattern in the foundry.

I have discussed below the single-piece pattern in casting with pattern diagrams, applications, advantages and disadvantages, mcq and summary.

{tocify} $title={Single Piece Pattern Table of Content}

Single Piece Pattern In Casting

What is a single piece or solid pattern?

A single-piece solid pattern is a pattern made up of a single solid piece used to create an impression or cavity in the mould to manufacture casting in the sand casting process.

The single-piece pattern is made without joints or sub-parts used to manufacture small and straightforward design castings.

Single piece/solid piece pattern in a foundry is only used for low-volume production of up to 100 units of castings.

Single-piece pattern in casting is designed in such a way that one side of the pattern is expected to be flat along the parting plane and the remaining part is in either the cope or drag section of the mould.

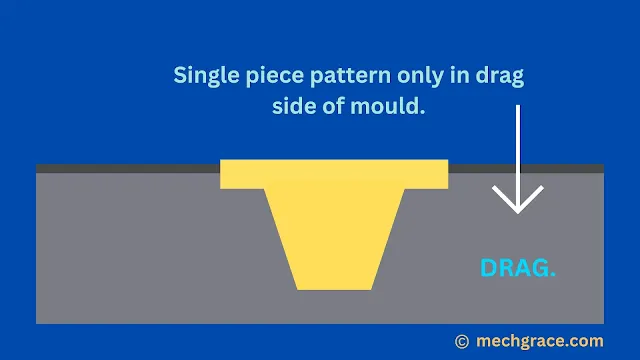

As shown in the diagram below (b) single/solid piece pattern resting in the drag section of the mould.

|

| (b) Solid Pattern Diagram |

A solid pattern usually has one board surface that serves as a parting surface in the mould.

Single-piece patterns are not attached to the frame or plate as compared to other patterns such as match plate patterns and cope and drag patterns.

As shown in diagram (c) below board surface serves as a reference point and support while placing the pattern in the drag section of the mould.

|

| (c) Single Piece Pattern Board |

The mould cavity is created mainly on one side preferably the drag side of the mould for smaller-size casting as shown in diagram (d) below.

|

| (d) Single Piece Pattern In Drag Side of Mould |

After the solid pattern in sand casting is placed in the drag side of the mould, sand is rammed around the pattern to create a mould cavity.

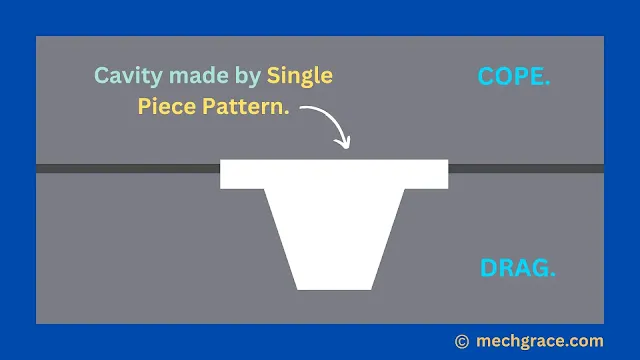

After the sand is been rammed, the pattern is taken out of the mould leaving the mould cavity behind as shown below in diagram (e).

|

| (e) Mould Cavity By Single Piece Pattern |

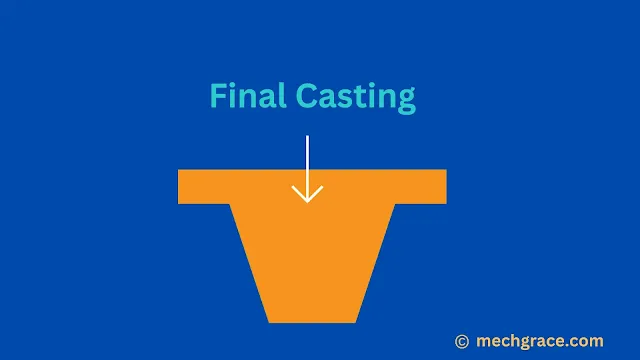

Molten metal is poured into this mould cavity to manufacture the desired solid casting as shown in diagram (f) below.

|

| (f) Single Piece Pattern Casting |

What is one piece pattern called?

One piece pattern can be also called as follows:

- Loose pattern.

- Solid piece pattern.

- Single-piece pattern.

Note: Loose pattern should not be mistaken for loose piece pattern in casting. Loose pattern and loose piece pattern are different.

What material is used for producing single-piece patterns?

Wood is the most preferred material for single-piece patterns but plastic and metal are also used.

I have written a detailed article on pattern material in casting that one must read to understand the concept better.

Along with material selection care is also taken to ensure proper pattern-making allowances are given to the solid pattern depending upon the type of casting to be produced.

Single Piece Pattern In Casting Advantages And Disadvantages

Single Piece Pattern Advantages

- Single-piece patterns in sand casting are inexpensive, cheap and cost-effective for producing mould cavities.

- The pattern is simple in design with no irregularities, joints, loose pieces, parting or attachments.

- Pattern making is easy to produce with carpentry or hand carving.

- The pattern design does not have any attachments or joints.

- Withdrawal of solid/single-piece patterns is easy as the pattern rests mostly on the drag side of the mould.

- Single-piece patterns may not have core prints.

- The durability of the pattern is high as this pattern is free from any joints or attachments, fewer moving parts means more durability.

- This pattern can be made from cost-effective wood pattern material.

Single Piece Pattern Disadvantage

- Single-piece patterns cannot be used for large-size casting.

- Is used for a limited number of casting as a riser, runner and withdrawal of pattern are done by hand.

- Production time and tooling costs for making solid piece patterns are less.

- Is limited to prototype-type casting with no automation facility available.

- Only small-size sand casting can be produced in the foundry with limitations over the shape.

- Only the drag side of the sand mould is utilized to cast the casting.

- Complex shapes and features cannot be produced, for complex casting multi-piece patterns are used.

- Single piece or solid pattern can be either on one side drag or cope. To create a mould cavity and casting with both sides cope and drag pattern, match plate pattern, split pattern and the multi-piece pattern are used.

- Difficult to produce casting with complex recesses, holes and cavities.

- Only one casting can be made during sand casting at a time.

Single Piece Pattern Application

Single-piece patterns are used for manufacturing the following products/casting.

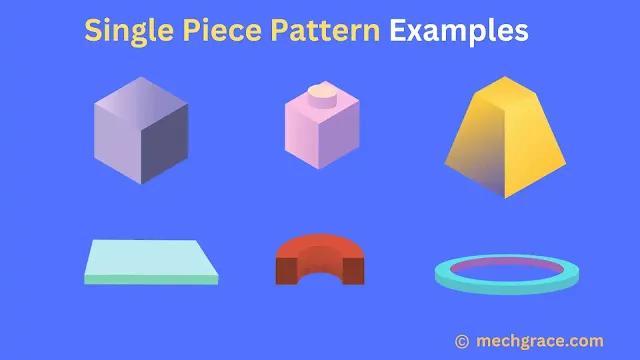

Single-piece pattern in casting examples are as follows:

- Typically gland of engines, blade housing, aluminium coving, solid temper, brass chain links and stuffing boxes are examples of single-piece patterns.

- The single-piece pattern is mainly used for producing small-size casting and prototypes such as spur gear, wire grippers, lock plugs, square blocks, rings, metal plates, soil temper, cylinders and spheres are applications that are manufactured using single-piece patterns.

Examples of single-piece patterns are shown below in diagram (g):

|

| (g) Single Piece Pattern Application |

Single Piece Pattern MCQ (Multiple Choice Question & Answer) / Practice Questions

1) Which of the following pattern is made from a single solid piece of wood or metal without any joints?

2) Which of the following pattern are best used for producing small-size prototype casting in the manufacturing industry?

3) Solid pattern/single piece pattern rests in which of the following part of the mould?

4) Single piece pattern does not have to align pins, screws and adhesives as part of the pattern (State if the statement is true or false)

5) Which of the following pattern is cheapest, simple, easy to design and produces small casting such as squares, plates and cubes?

Single Piece Pattern Summary

Solid pattern is one of the patterns among 17 types of pattern in casting.

Only one casting can be made from a single piece pattern at a time as compared to a match plate pattern and gated pattern in the casting where multiple castings are made together.

This pattern does not have any parts that are joined together using adhesives, pins and press fits techniques as compared to other patterns such as two-piece patterns, multi-piece patterns, gated pattern in casting, cope and drag patterns, skeleton patterns and match plate patterns.

The solid pattern in casting sits on either side of the parting line either on the drag or cope side of the mould but the drag side of the mould is mostly preferred as pattern can be taken out easily after the mould cavity is produced.

The single-piece pattern is used for manufacturing simple sand casting in the foundry but for more complicated design casting two-piece pattern and the multi-piece pattern are used utilizing both the cope and drag parts of the mould.