Split Piece Pattern Introduction

|

| Split Pattern In Sand Casting |

Solid piece patterns can produce casting only on one side of the mould (either cope or drag). When there is a requirement for producing casting which has depth and height split-piece patterns are used.

I have written a detailed article on split patterns in casting discussing split pattern design, advantages, disadvantages, application and MCQ (multiple choice questions)

Students/professionals are advised to use the navigation bar below to navigate through the split-piece pattern article.

{tocify} $title={Split Pattern Table of Content }

Split Piece Pattern In Casting

What is a split pattern or two-piece pattern in casting?

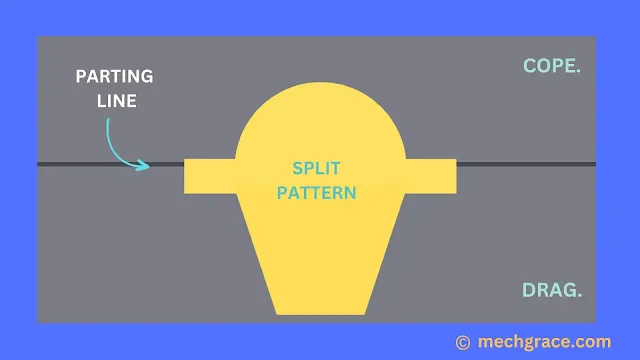

A split pattern in casting is a pattern made from two split pieces joined together by dowel pins, adhesives, press fit and screws that will rest in the cope (upper part of the mould) and drag (lower side of mould) to create a mould cavity in the sand casting process.

A split or two-piece pattern is designed in such a way that the pattern is split along the parting line or parting plane.

As shown below split pattern in diagram (a), one part of the pattern rests in the cope section of the mould while the other part of the split pattern rests in the drag section. As shown in diagram (a) the pattern is divided along the parting line.

|

| (a) Split Pattern Diagram |

Care must be taken to ensure that parts are aligned together to avoid misalignment and warping.

A split pattern is used in the sand casting process to produce intricate, irregular, unusual shapes which cannot be made from a single-piece pattern as shown below in the below diagram (b)

|

| (b) Casting From Pattern Cavity |

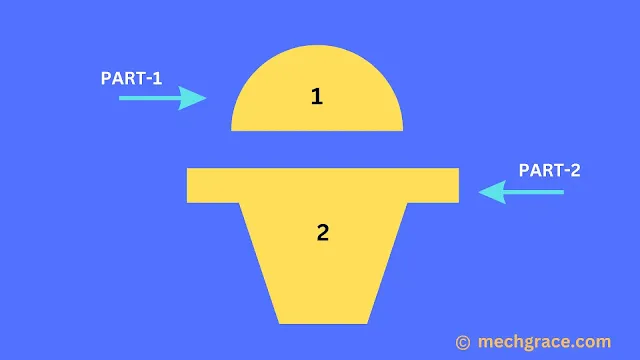

Both sides of a split-piece pattern may or may not be of the same size and shape as shown below in diagram (c).

Part-1 of the split pattern which rests on the cope side is different from part-2 of the pattern which rests on the drag side.

|

| (c) Two-Piece Pattern In Casting |

Why is a split pattern used in sand casting?

A split pattern is used in sand casting to manufacture complex casting that cannot be produced by a single-piece pattern due to limitations over the shape and size of the pattern design.

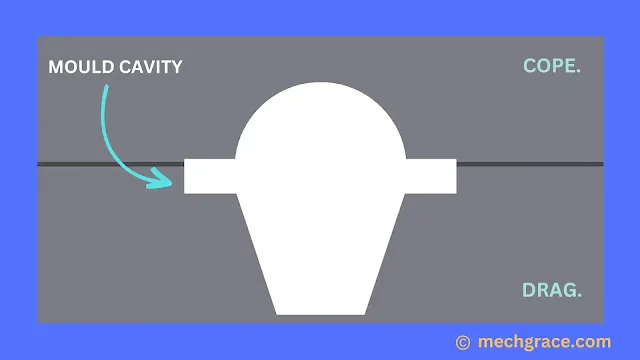

A split pattern makes a mould cavity in both the cope and drag side of the mould as compared to the solid pattern where the cavity is made only in one side of the mould along the parting plane where the molten metal is poured into to make a sand casting.

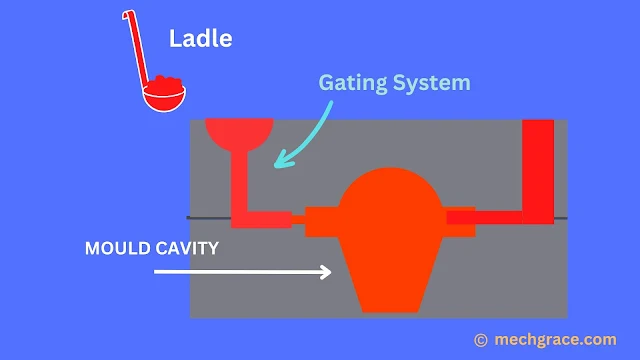

The mould cavity where molten metal will be poured in the mould cavity is made from the split pattern as shown in diagram (d) below.

|

| (d) Mould Cavity From Split Pattern |

The pouring operation in the cavity made from a two-piece pattern is shown below in diagram (e).

|

| (e) Pouring Operation In Split Pattern Mould Cavity |

Sand casting produced from the two-piece pattern in the casting process is shown in diagram (f) below.

|

| (f) Final Split Casting |

What is the upper part of a split pattern called?

The upper part of the split pattern is called the cope side of the mould box. Split patterns are divided into two parts, Upper part is called the cope and the lower part is the drag side of the mould.

What is split piece pattern also known as?

The split pattern is also known as follows:

- Two-piece pattern.

- Split pattern.

- Parted pattern.

- Split piece pattern.

What material is used for producing a split pattern in casting?

Wood is preferred for making split patterns, two parts of a pattern are made separately by carpenters and then joined together. The split pattern can also be made of metal, plastic and form.

The pattern material used for making two-piece patterns depends upon various applications, final casting and types of patterns.

During pattern making different types of allowances are added depending on the material and application of casting.

How are split pattern pieces joined?

Split piece pattern in casting is assembled together by dowel pins, clamps, adhesives and screws and bolts.

Why is a split pattern preferred over a solid pattern?

Split patterns can manufacture a variety of complex shapes and non-symmetrical split castings that cannot be manufactured/cast by single-piece patterns in the foundry.

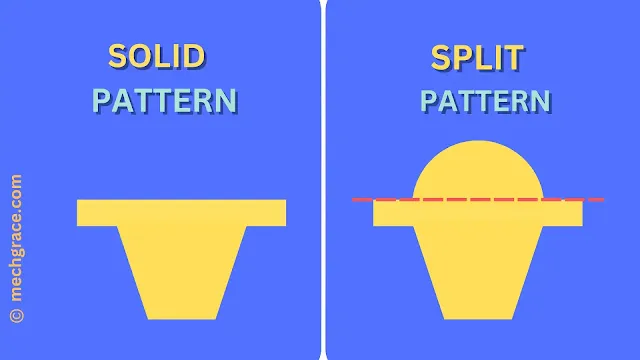

What is the difference between the solid pattern and the split pattern?

|

| (g) Solid Pattern Vs Split Pattern In Casting |

| Solid Pattern In Casting | Split Pattern In Casting |

|---|---|

| 1) A solid piece pattern is a single-piece pattern which sits mostly on the drag side of the mould only. | 1) Split pattern is split into two parts along a parting line and the rest in both cope and drag part of the mould. |

| 2) More pattern material, time and resources are required than a single-piece pattern. | 2) Less pattern material, time and resources are required than split piece pattern. |

| 3) The pattern has no joints and attachments it is a single piece. | 3) Two patterns are joined together to make one pattern by joining them with pins, adhesives and screws called the split pattern. |

| 4) Withdrawal of patterns from the mould is difficult. | 4) Withdrawal of patterns from the mould is easy. |

| 5) Limitations over height and depth of the pattern. | 5) Patterns can be made with more height, depth and width as compared to solid patterns. |

| 6) Only one side of the mould is utilized. | 6) Both sides of the mould are utilized. |

| 7) Solid pattern makes simple shape castings such as gear blank, wire gripper, metal plates, cubes and spheres. | 7) Split pattern is used to make valves, dumbbells, kitchen taps and casing. |

Split Piece Pattern In Casting Advantages & Disadvantages

Split Pattern In Casting Advantages

The benefits/merits of split piece pattern are as follows:

- Non-symmetrical complex design casting can be produced utilizing the entire mould relative to single-piece patterns.

- A split-piece pattern is best for casting where the depth of the casting is greater, and the pattern can be split into two halves.

- The flexibility of designing different shapes on both sides of the pattern along the parting line.

- The size and height of the pattern can be increased as compared to a single-piece pattern.

- Each section of the split pattern can be designed independently according to the demand of the customer.

Split Pattern in Casting Disadvantages

- Care must be taken to ensure there is no mismatch during the alignment of the pattern to avoid casting defects.

- Pattern-making is more time-consuming than solid patterns.

- The design of a pattern is more complex than the single-piece pattern.

- For larger and more complex casting engineers need to shift to multi-piece patterns and cope and drag patterns.

- The cost of pattern production is more than solid pattern.

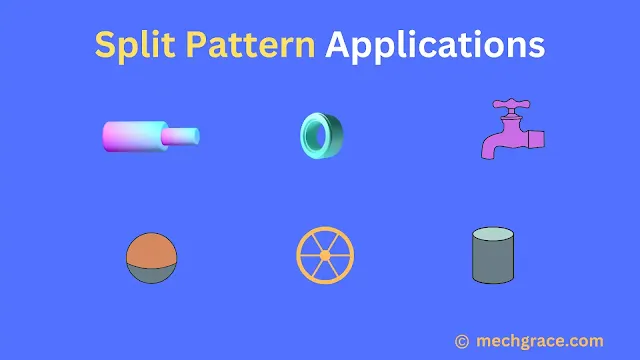

Split Pattern Application

|

| (h) Split Pattern Application |

What is a split pattern generally used for in casting?

Split patterns in casting are generally used to manufacture the following casting products in the foundry. I have listed split-piece pattern examples below:

- Spindles.

- Pneumatic hand tool split handles.

- Steam valve outer casing body.

- Dumbells.

- Gear case housing assembly.

- Zinc casket.

- Rocket arms.

- Wheels.

- Kitchen faucet hub and taps.

- Cylinder.

- Bearing.

- Headlamp visors.

- Water tabs.

- Small pulleys.

- Small cylinders.

- Automatic clutch housing.

A two-piece pattern can manufacture complex casting that can be split into two parts in the manufacturing process.

Split Piece Pattern MCQ (Multiple Choice Question & Answer) / Practice Questions

1) Split piece pattern rest in which part of mould?

2) Split patterns can produce more intricate and complex casting than which of the following patterns mentioned below?

3) Split patterns are split or divided into how many parts?

4) The cost of production of the split pattern is higher than the solid piece pattern (State if the statement is true or false)

5) Which of the following parts is produced by a split pattern in casting?

Two Piece Pattern or Split Piece Pattern Summary

The split pattern is one of the patterns among 17 types of patterns in moulding.

Split piece patterns are used when the casting requirements are not fulfilled with solid piece patterns.

Split patterns always rest on both sides of the mould, one half of the split pattern is on the drag side of the mould while the other half is on the cope side of the mould.

A two-piece pattern is an improvised version of a single-piece or solid pattern which is split along the parting line. This complex pattern is balanced along the parting line to produce intricate shapes that cannot be produced by a single-piece pattern.

The parted pattern is used for making more complex, irregular, intricate shapes that cannot be produced with a solid piece pattern.

Split-piece patterns can make only one casting at a time in the mould as compared to match plate patterns.