Sand Mould Making Process Introduction

|

| (a) Sand Mould Making Process |

What are the basics one must know before learning the sand mould-making process?

The sand mould-making process is the process of using sand as the main component for producing sand moulds to manufacture casting of desirable shapes in the foundry. The main function of the sand moulds is to hold the molten metal together from the pouring operation to complete the solidification of the molten metal while manufacturing sand casting.

Moulds that are used for making sand casting are of three types depending upon the size, shape, type of sand used and complexity of casting to be produced.

Types of sand moulds produced in the foundry to manufacture casting are as follows:

Green sands are collected from the river beds, cleaned and used for making green sand mould directly to manufacture small green casting. Dry sand is basically a dried version of green sand. Green sand is dried in the oven removing all moisture and used for making dry mould for manufacturing large-size casting.

Both green sand and dry sand are used in combination to produce dry sand mould.

Pattern tool is utilized to make cavities in these sand moulds mentioned above so that molten metal can be poured to cast desirable final casting according to customer requirements.

The mould-making process starts in the foundry by selecting proper moulding material such as mould sand, additives and binders based on casting shape, size, type, weight, accuracy, dimensions and surface finish.

{tocify} $title={Sand Mould Making Process Table of Contents}

What types of sand, testing equipment, machines and tools foundry must have before we start making sand moulds?

For making dry sand mould and green sand mould in the foundry following sands, tools and testing equipment a foundry must have.

- Different types of moulding sand should be readily available such as green sand, facing sand, dry sand, moulding sand, backing sand, parting sand and loam sand.

- Mould-making materials such as binders, special sands and additives are used to give strength to the mould. Binders such as resin and silicate sand (for dry sand mould) and clay for green sand moulds. Along with binders additives such as sawdust, wood flour, coal dust etc. are used to support the moulding structure reducing mould defects. Examples of some special sand used in the sand moulding process are silica sand, zircon sand, chromite sand and olivine sand.

- Sand testing equipment such as moisture content tester, compatibility tester, permeability tester, hardness tester, GFN test, clay content tester, compression, shearing and tensile strength tests for green and dry sand.

- Moulding tools and equipment used in the sand mould-making process are listed in the following topics below.

The moulding process can be classified in two ways:

- Hand Moulding

- Machine Moulding

Hand Moulding Tools Used For Making Sand Moulds

What moulding tools and equipment are required in the foundry for making sand moulds?

Moulding hand tools required for hand-making sand moulds are as follows, these tools do not require any power supply they are used manually by the skilled operators. These tools are handly in small foundries where the mould-making process is manual.

Shovel

|

| (b) Shovel For Making Sand Mould |

The first step in mould mould-making operation is to pour different types of sand into the moulding box (flask) or in a pit mould. This entire operation can be done manually and automatically.

When sand is poured into the flask shovels by operator's manually shovels are used to pour sand into the flask or in the pit mould.

Trowel

|

| (c) Trowel Used To Repair Mould During Mould Making Process |

During the sand mould-making process it becomes important to repair, restructure, correct and align the mould. This operation is done by trowel. The trowel is a wooden handle tool with a flat metal blade with square and rectangular ends having curved edges.

The surface of the blades is made smooth so smoothen the surface of the sand mould.

Slick

|

| (d) Slick Used For Sand Mould Repair |

Slick is a type of trowel with a major difference in the shape. Slick looks like a double oval spoon end tool having a curved surface for small repairs, correction, smoothness and finishing of the sand mould. Slick is used for small repairs of mould while trowel is used for major repairs in the foundry.

Rammer

Well, there are two types of rammer. Machine automatic rammer and hand rammer. For making smaller sand casting moulds in a small foundry hand rammers are most preferred as they are cost-effective.

Sand ramming operation majorly depends Tol of the operator and experience in sand ramming.

Rammer tool is made from wood as it becomes lightweight and has two ends to it. One end is called peen while the other end is called butt. Rammer is used to compact the sand after the sand is poured into the flask by shovel.

Strike-off Bar

|

| (e) Strike-off Bar Used To Remove Excess Sand During Sand Mould Making |

Strike-off bar is used to level the sand during the sand moulding process. This bar is light in weight and made from wood or metal. As the name says this bar is used to strike off unnecessary sand after a ramming operation.

Lifters

|

| (f) Lifter Moulding Tool |

Lifters are thin and pointed right-angle bend bars made from stainless steel used to shape, scrape, clean and finish corner edges of the moulds. Lifters are made light in weight but strong with a good grip making it easy for mould makers to use them.

These lifters are made lengthy so an operator can reach the bottom of the sand moulds without any fatigue especially when making pit moulds which have higher depth as compared to floor moulding moulds and bench moulding sand moulds.

Riddle

|

| (g) Riddle Used To Filter ForeignTohile Sand Mould Making |

Sand used for making moulds is directly brought from the sea bed to the foundry. The initial stage of sand inspection and testing consists of separating foreign material from the sand.

This is done by a tool called a riddle. A riddle is a manual tool which is basically a sieve attached to a circular rim. Mesh sieves and rims are made from stainless steel.

Sand is passed through the sieve and foreign materials such as metal pieces are separated from the sand, when using backing and moulding sand there are residues of additives, binders, metals, chips and wood remaining in the sand.

Clamps and Pouring Weight

|

| (h) Clamps Used To Hold Cope & Drag the Side Of Sand Mould Together |

When molten metal is poured into the mould there is a tendency for the mould (cope) to rise. In order to prevent this clamps are introduced that clamps cope and drag together.

Pouring weight serves the same purpose. Heavy cast iron weight block is placed on the mould to reduce the impact of cope raising and separating from the mould.

Rapping Plates and Spikes

|

| (i) Rapping Plate Used To Hold Sand Mould Together In Sand Casting Process |

When a cavity is formed in the mould next step is to remove the pattern from the sand mould. This is done by spikes and rapping plates.

Plates and spikes are attached to the pattern with screws and withdrawn from the mould after the mould cavity is formed.

Draw spikes or screws are mostly used for lightweight patterns made from wood and plastic. While rapping plates are preferred for large-size wood and metal patterns.

|

| (j) Draw Spikes For Pattern Withdrawal |

Using pattern withdrawal tools reduces enlargement of the mould cavity during pattern withdrawal operation reducing the rapping allowance in the pattern.

Mallet

|

| (k) Mallet Sand Moulding Tool In Sand Casting Process |

When the pattern is used for making mould cavities due to the adhesive property of the moulding sand, sand sticks to the pattern.

In order to remove this sand pattern is loosened by applying a small force on the pattern with a mallet which looks like a small hammer made from plastic, silicon or rubber.

Swab

|

| (l) Swab To Induce Moisture In The Sand Mould |

When using a green sand mould it becomes necessary to moisturize the green sand mould, A swab as a tool is used for spraying water or paint with high pressure.

Bellow

When the pattern is withdrawn from the mould, the pattern has some sand clinging to it. This sand needs to be removed from the pattern as the pattern is a tool which needs to be used again.

This is done by bellow which is a hand blower which emits pressurized air on the pattern blowing air seprating sand from the pattern.

Gate Cutter, Sprue Pin and Riser Pin

|

| (m) Sprue Pin Used To For Making Sprue Cavity In The Sand Mould |

A gate cutter is used for cutting gates and runners.

These pins are of different shapes and sizes and are made from wood and used to make runners and sprue. A sprue pin is used for making vertical tapered sprue in the mould. A riser pin is used to make the riser.

Spirit Level

|

| (n) Spirit Level To Check Flatness Of Mould |

When making a mould it becomes important that the process takes place on a flat horizontal surface. The surface here can be a floor, bench or even a pit. To check if the surface is flat spirit level is used for checking the flat surface.

Spirit level has a bubble in it which indicates if the surface is horizontal or not. If moulding is to be done on an uneven surface it will cause misalignments and defects in the final casting.

As we now know about the tools required in the foundry let us start learning about how moulds are made in the foundry with hands and machines.

Sand Mould Making Process

Depending upon the type of casting, foundry size, material, sand used, production cost, production order, production time, operator skill, the shape of the casting, final accuracy of casting and the tolerance limit the sand mould-making process is selected. There are two ways in which sand can be produced in a foundry.

- Hand moulding

- Machine moulding

Hand Moulding Process

Hand moulding is still done in small foundries having less production volume and production budget. This process is time and labour-consuming and has been replaced in larger foundries where moulds are produced directly with machines.

Hand moulding is the most economical way of making different types of moulds in the foundry. Hand moulding starts with an experienced skilled foundryman using various kinds of mould sand, resins, hand tools and equipment to make a mould for the casting process.

Hand moulding is a cost-effective way to make mould but is time-consuming for mass production of moulds.

To address this problem machine moulding is used in foundry to produce moulds in less time and in larger quantity.

This hand mould-producing method is still an interesting method for producing moulds. Below I have written a detailed step-by-step explanation of producing moulds.

Step By Step Process To Make Sand Mould

A) Making Drag Side Of Sand Mould

A flask is used to hold the entire sand mould together. The function of the flask is to hold the mould intact during mould mould-making process and provide strength, rigidity and support to the moulding sand.

Layers of sand are added to the moulding box with the support of bottom board. A follow-up board must be used when the pattern is delicate, thin and fragile to avoid breaking of pattern during a ramming operation.

A flask is an important element in the moulding process that shapes the final mould.

The process of making a sand mould starts with making a drag section of the mould first and then making a cope section.

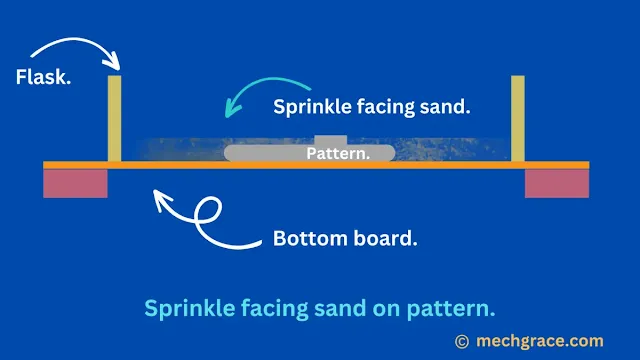

A1) Sprinkle Facing Sand On Bottom Board

The pattern is placed on the bottom board and the board is sprinkled with facing sand as shown in diagram (o) below.

|

| (o) Sprinkle Facing Sand On The Bottom Board |

Facing sand is applied after the parting compound for a better surface finish in the final casting.

The pattern is powdered with talc and graphite up to 2mm layer above facing sand.

A2) Pouring Moulding Sand In Flask

After facing sand, moulding sand or system sand is poured that covers the entire pattern and bottom board as shown in diagram (p) below. The bottom board is also called the moulding board.

Moulding sand has a major role in forming the mould cavity made by mixing sand, clay and moisture.

|

| (p) Pouring Moulding Sand On Pattern |

Moulding sand up to 80mm to 100mm layer is poured on the facing sand. Moulding sand is rammed and the flask is kept ready to pour backing sand.

Sand is rammed into sand particles that are closely compact sand particles closely with each other to form strong sand mould during the sand mould-making process.

Ramming reduces the mould cavity to enlarge when the molten metal comes in contact with the mould cavity.

A3) Pouring Backing Sand On Moulding Sand

After moulding sand, we now pour backing sand which is the last sand to be poured in the drag section that "backs" the entire mould as shown in diagram (q) below.

|

| (q) Pouring Backing Sand On Moulding Sand |

The strickle bar removes any excess sand. Any excess sand is removed by the strike-off bar and ramming is done to compact sand again.

Venting of mould is done so any excess gasses formed during the moulding process get out of the mould reducing casting defects.

A4) Drag Side Of Mould Is Ready

At this point, the drag side of the sand mould is ready as shown below in diagram (r).

|

| (r) Drag Side Of Sand Mould |

A5) Inverting The Flask For Cope Preparation

Once the drag side is made bottom board is now inverted and the cope side of the mould is made as shown in diagram (s) below.

|

| (s) Inverting Mould To Make Cope Side Of Sand Mould |

This approach to making drag sides is called the bedding approach.

B) Making Cope Side Of Sand Mould

Once the bottom board is inverted the cope side of the mould begins.

Making the cope section of the mould is similar to making the drag section of the mould.

At this point both the cope and mould are held together with the help of clamps and rapping plates.

The process starts with sprinkling parting sand and facing sand.

Sprue pins, runner pins and vents are provided to make a gating system in the mould.

System sand is poured at the end to fill the moulding flask. System sand supports the entire mould and allows gases to escape the gas.

B1) Pouring Moulding Sand For Making The Cope Side Of The Sand Mould

The process of making cope is similar to that of making drag side.

|

| (t) Pouring Moulding Sand On the Pattern To Make Cope |

Facing sand and moulding sand or system sand is poured into the flask to produce the cope section shown in diagram (t) above.

B2) Pouring Backing Sand Over Moulding Sand To Make the Cope Side Of The Sand Mould

|

| (u) Pouring Backing Sand To Fill The Sand Mould |

After moulding sand, backing sand is poured over the moulding sand to make a cope section as shown in diagram (u) above.

Mallet is used for losing the pattern so it can be withdrawn peacefully from the sand mould without disturbing the mould cavity.

Finally, lifting plates lift the pattern out of the mould.

C) Pattern Removal From Mould

During the sand mould-making process, the pattern remains in the mould to retain the shape of the mould cavity.

This pattern needs to be removed from the mould cavity before the mould is cured/baked in the oven.

Rapping of the pattern is done to remove the pattern from the sand mould.

Appropriate rapping allowance or shake allowance is provided during the mould-making process to compensate for the change in the dimension of the mould cavity during the rapping operation in the foundry.

After the pattern is removed air blowers are used to blow loose particles of sand in the mould cavity.

Foundry blacking sand is sprinkled on the mould cavity to give a better surface finish to the final casting. This sand eliminates surface defects and metal penetration into the mould resulting in a shiny surface finish instead of a rough surface.

D) Cutting Pouring Basin, Sprue, Runner, Riser, Gate and Vents In The Sand Mould

After the pattern is removed the gating system (pouring basin, sprue, gates, runner and riser) is cut in the mould to ensure proper flow of molten metal into the mould cavity as shown in diagram (v) below.

|

| (v) Cutting Gating System In Sand Mould |

Sprue pin and riser pin are used to create

sprue

and

riser

impressions in the mould respectfully.

Filling, ramming and venting are done in the sand mould for both the cope and drag sections during the sand mould-making process.

Vents wires are made to create vents to escape gases from the mould during pouring and solidification operations.

Ambient conditions, aeration, material handling, and sand transfer can lead to evaporation of the moisture in the green sand mould. Thus, this process needs to be done faster to retain the compatibility of the green sand mould.

E) Cope and Drag Mould Assembly

Aligning pins are used to align cope and drag mould sections together.

|

| (w) Sand Mould Assembly With Aligning Pins |

At this point cope and drag are assembled to form a single mould as shown in diagram (w) above.

Now we have a mould with a cavity with an exact replica of the final casting along with the gating system.

|

| (x) Sand Casting Mould |

The mould is ready now for pouring operation to pour molten metal into the sand mould as shown in diagram (x) above.

F) Mould Curing

The mould prepared till now is a green sand mould which is the sand used for making the green sand moulding process.

This mould has moisture in it not suitable for casting with a higher surface finish. To make strong mould engineers in the foundry engineers will put the green sand mould in the oven to cure it to make a dry sand mould the for dry sand moulding process.

Curing of mould is done to make the dry sand mould.

G) Pouring Of Molten Metal

After the sand mould is made pouring operation takes place in the sand casting process.

I have discussed the remaining operation of the sand casting process in the sand casting article.

Hand Moulding Disadvantages

Hand Moulding Disadvantage

- Hand moulding is time-consuming.

- The accuracy of mould-making is less than machine moulding.

- Mould-making accuracy depends upon mould-maker skill.

- More than one skilled mould maker is required to make a sand mould.

- Low-quality casting is produced if moulds are not up to standard.

- Mass production of moulds is not possible with hand moulding.

- Difficulty in handling heavy-weight mould.

- The productivity of the foundry reduces when there is a dependency on hand or manual moulding.

Machine Moulding Process Advantages

What are the advantages of Machine Moulding?

Machine Moulding Advantages

- Less time for producing moulds.

- Better accuracy and close tolerance of mould-making can be achieved.

- Skilled workers are not required in machine mould making.

- Labour costs are low.

- Suitable for mass production of moulds.

- Many types of moulds such as sand moulds, resin moulds and plaster moulds can be produced in the foundry.

- Uniform result and consistency in producing moulds.

- The machine can handle heavy-weight moulds.

- Material handing is reduced in machine moulding as compared to hand moulding.

- Green sand, dry sand and skin-dry sand moulds can be made at one station.

- The quality of casting produced from moulds made by machines is high.

- Pattern removal from the mould does not depend upon the skill of the worker.

- Better productivity of the foundry is achieved as there is a reduction in defective moulds made by machine moulding.

Sand Mould Making Conclusion

Sand moulds are an essential part of making sand casting in the sand casting process.

Mould can be made from green sand or dry sand depending upon the requirement of the customer such as tolerance limit, surface finish and accuracy of the casting.