Investment Casting Process

|

| (a) Investment Casting Diagram |

Investment casting is a type of special casting process used to manufacture

complex and highly accurate casting with tight tolerance with the help of

wax patterns and ceramic mould.

This process is also called the lost wax casting process, precision investment and precision casting.

The investment casting process is a special casting process giving versatile casting output using a variety of high-quality metals and alloys producing single crystal equidistance solidified casting.

This article describes all operations and steps required to manufacture investment casting.

Why this process is called the investment casting process?

This process is called the investment casting process because the refractory ceramic slurry consists of alumina and silica surrounding the wax material pattern.

Does this process have a better surface finish than sand casting and investment casting?

Yes, this investment casting has better surface finish and dimensional accuracy than the sand casting process and die casting process.

{tocify} $title={Investment Casting Process Table of Contents}

What Is Investment Casting And What It Is Used For?

Investment casting gives better surface finish, dimentional accuracy, netshape casting without use of draft.

Investment Casting Step-By-Step Process

Before the process of making pattern, die mould, refractory mould and casting starts entire process is stimulated in casting simulation software to check for projected problems, inconsistency, defects, damage, loss and time required for the entire process.

This reduces the multiple trials and errors during the actual casting process and the process moves ahead of manufacturing accurate casting at the first attempt.

STEP 1: Master Pattern & Die Making

The master pattern is made first, based on this pattern, a metal die will be made and wax will be poured into this master die to produce the wax pattern that will be assembled further.

Master patterns can be made from pattern materials such as metal, clay, wood or plastic which is a reference point for producing metal die cavities.

Master die is made from cast iron and tool steel metals

Note: The master pattern here represents the first pattern that is used as a reference point for producing metal die, engineers should not confuse this pattern with the wax pattern that is used for producing refractory ceramic mould.

The master pattern is always the reference point for producing metal die for manufacturing wax patterns.

All pattern allowances are considered and implemented before manufacturing the final master pattern, master die, wax pattern and final casting.

Master die is the one which produces wax pattern so die must be manufactured keeping in mind both shrinkage of wax pattern and shrinkage of the ceramic mould.

Dimension allowances of the master die must be on the higher side keeping in mind these two shrinkages.

Master die can be created without making the master pattern but for visual clearance of engineers, pattern allowances techniques this pattern is made.

These days advanced techniques are used to 3D print the pattern directly. Further, these patterns can be directly used for making pattern trees.

Master die is made out of metal using Casting, ECM, EDM, LBM and AJM to produce accurate die cavity.

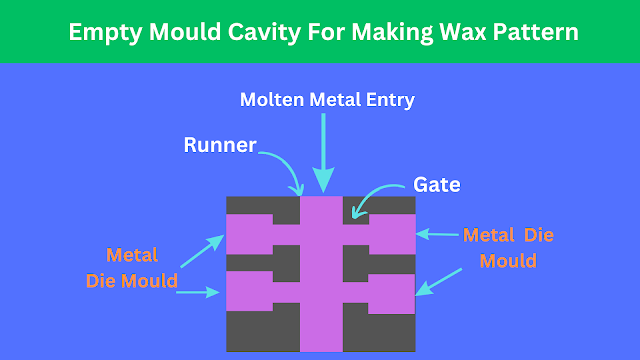

STEP 2: Wax Pattern Production

|

| (b) Empty Mould Cavity For Making Wax Pattern |

After we are done with producing the master die it is time to produce a wax pattern. This wax pattern is an exact replica of the part to be manufactured.

Types of wax used in this process are beeswax, paraffin wax, water-soluble wax, specialist wax, repair wax, hard wax, microcrystalline wax, sticky wax, filler and non-filler pattern wax and runner wax based on the type of application and products in the investment casting process

Wax patterns are manufactured with the help of a master die where molten wax is poured into the die cavity and wax is allowed to solidify.

Cores are adjusted in the wax patterns which are soluble wax cores. Non-soluble ceramic cores can also be placed in the wax patterns before pouring the wax into the cavity to produce complex non-uniform casting.

Once the wax pattern is solidified in the die cavity, it is taken out for final finishing before the assembly.

|

| (c) Empty Mould Cavity For Making Wax Pattern |

As the wax melts more easily than any other pattern material, this pattern is finished, parting lines are removed and edges are sharpened with the heat gun and tools to remove any imperfections in the pattern.

Other replacements for wax pattern material are mercast which is a combination of plastic (polystyrene and polythene) and mercury. More materials used for the process are plastic and thermoform.

STEP 3: Pattern Tree Assembly

These wax patterns are assembled together to form a tree-like structure called tree/cluster pattern assembly having a common runner connecting every pattern with the ingate.

These patterns are assembled together using stocky wax, a heating torch and pins to the gating system.

At this point, the wax pattern assembly is ready to be dipped in the ceramic slurry liquid, which includes water and alumina and then dipped into a stucco of fine silica sand, zircon and binding agents.

This pattern assembly is dipped and removed from the slurry multiple times to form multi-layers on the assembly.

This slurry on the assembly is allowed to dry and cool at room temperature, after this step the assembly is de-waxed which is mentioned in the next step-4 below.

The advantage of using a metal die is multiple pattern clusters can be mass-produced at the same time having a common sprue, runner and in-gates.

This process is best for components that need to be further joined by the fabrication, laser beam welding and traditional welding processes.

The wax pattern assembly tree gives an added advantage to branch out patterns according to the final casting design to eliminate any secondary joining manufacturing operations.

This step gives huge advantages and flexibility in designing the moulds according to the requirements.

STEP 4: De-Waxing And Shell Mould Production

Investment is where the wax pattern is dipped in the ceramic or plaster slurry to make the refractory accurate shell mould.

Refractory moulds are manufactured using slurry which is a mixture of ceramic, quartz, sodium silicate, colloidal silicate, zircon, alumina, aluminium silicates, fused silicates, chamotte, zirconium, ethyl silicate and other binder agents.

|

| (d) Dipping Wax Pattern In Ceramic Slurry To Make Ceramic Mould |

The wax pattern is dipped in ceramic slurry and slurry is allowed to coat the pattern with a ceramic coating having a mixture of resin, alumina and silica as shown above in diagram (e).

This coating is now allowed to solidify on the pattern, to this point, the pattern cluster remains undisturbed.

Once the coating is solidified around the wax pattern it is time to drain the wax pattern out by heating the mould as shown below in diagram (e).

|

| (e) Heating Mould To Drain Wax Out Of The Ceramic Mould |

The de-investing process is where this wax pattern is melted and drained out of the refractory ceramic mould by inverting the refractory mould.

After the wax/plastic is drained out the casting is dried out for 2 to 3 hours and baked in the oven up to 100℃.

All wax is drained out at this point and what remains is a thin accurate mould cavity as shown below in diagram (f) where molten metal will be poured to manufacture the final casting.

|

| (f) Ceramic Mould After Wax Is Drained Out |

Before pouring molten metal the refractory mould is cured and hardened to sustain the casting process to avoid the final casting from getting uneven and inaccurate tolerance casting.

Any voids, inconsistency in the mould, small corrections, changes in dimensions or finishing touches are given to the refractory mould before using the mould for the casting process.

STEP 5: Pre-Heating And Pouring Operation

|

| (g) Pouring Molten Metal Into Ceramic Mould |

Before pouring molten metal into the mould, the mould is preheated at around 70℃ to 1000℃ to remove any residual wax, unwanted holes, gaps, inclusions and cracks and eliminate any moisture content in the mould.

Preheating the mould reduces the molten metal getting into contact with the mould and metal getting stuck to the cold surface of the mould causing surface defects such as cracks.

This is also done to remove any moisture content in the mould that can cause gas defects such as blowholes, pinholes and porosity defects in the final casting.

After the mould is pre-heated the molten metal is poured into the refractory mould that we early produced as shown in diagram (g) above.

Molten metal flows through the gating system such as sprue, a common runner connecting all cavities in the mould and metal entering individual in-gates into the mould cavity.

The runner system is equipped with stopping any slag and inclusions from the molten metal but care must be taken that impurities, oxides and slag do not reach the final casting and should be removed before the molten metal is poured in the sprue through the ladle.

Molten metal enters into every small detail and section to produce high-quality sound precision investment casting with the highest surface finish in less energy and cost.

While molten metal is solidified in the casting, there is expected to be uniform directional solidification in the casting, creating an equidistance uniform column grain growth with proper dendritic space structure providing better mechanical properties to the final casting.

Spacing between the growths should be fine to reduce casting defects and the heat treatment process.

No external force is required in this process as we have seen in vacuum die casting, die casting, centrifugal casting, tilt casting and injection moulding.

STEP 6: Shake Out And Finishing Operation

|

| (h) Final Investment Casting Products |

After the casting has solidified it is time to separate the final casting and the mould by knocking them out as shown in the diagram (h) above.

Inspection and testing are carried out on investment casting which includes non-destructive testing (NDT) such as magnetic particle, geometry testing, radiographic, x-ray test and florescent penetration test.

This process is a non-expandable non-permanent moulding process which requires breaking the mould and gating system from the casting to take out the final casting.

Solidified casting is separated from the sprue, runner, in-gate and common runner.

Casting is separated from each other by hammering, chipping, sawing, cutting, vibrating the moulds on a vibrating table, media blasting, breaking with liquid nitrogen and pressurising waterjet on the mould to break it.

STEP 7: Finishing Operation

After this step, the casting is cleaned properly for the finishing operations.

Investment castings have the least finishing, machining and secondary process operation as compared to all casting processes.

Casting goes through a heat treatment process such as hardening, austempering, normalizing, case hardening, quenching, carburizing, carbon-restoration, carbon-nitriding and annealing to improve the quality of casting, reducing internal stresses, increasing hardness, reducing brittleness, weldable, machinability, dimensional stability and improve the strength and properties of casting products.

Products go through a basic cut-off, trimming, deburring, grinding, CNC machining, drilling external drill holes, reaming, treading boring, welding for components that are to be joined further, shot blasting, sandblasting, powder coating, oxide coating, and polishing of the casting components.

Polishing is the process where casting surfaces are polished removing unevenness, uncertainty, and imperfection in the visual appeal of the casting giving a highly reflective aesthetic-looking finished shiny casting surface.

Investment casting is subjected to a process called anodization where a coating of oxides is applied to the aluminium casting protecting it against corrosion, sunlight and dust and giving an aesthetic appeal to the surface of the casting.

Painting and powder coating is the process of covering the casting with the surface to protect the casting in the long run from harmful chemicals, increasing its functional life, giving the surface proper texture, making it visually appealing applying proper colour and protecting it from environmental elements and hazards.

Apart from the secondary manufacturing process mentioned above chemical film coating, passivation, electroplating, galvanising, electropolishing, zinc plating, nickel coating and vibro-polishing are done on the casting.

Investment Casting Material

What materials are used for the production of investment casting?

This casting can be manufactured using the following materials. Ferrous, non-ferrous, pure metals, alloys and supper alloys can be used for producing precise casting. The list of materials used in this process is as follows:

- Bronze.

- Brass.

- Aluminium.

- Glass.

- Magnesium.

- Copper.

- Steel.

- Steel alloys.

- Stainless steel.

- Tool steel.

- Carbon steel.

- Heat resistance steel.

- Grey iron.

- Ductile iron.

- Iron.

- Nimonic alloy.

- Titanium.

- Nickle.

- Cobalt and based alloys.

- Lead.

- Tin.

- Gunmetal.

- Glass.

Investment Casting Advantages

- Suitable for producing complex shapes having counters, passages, varying thickness casting and thin sections symmetrical and a-symmetrical casting with high accuracy that cannot be manufactured from squeeze casting, forging process, sand casting and die casting.

- The environmentally friendly wax used in this process can be recycled and reused.

- A variety combination of wax is available based on softness, hardness, colour, flow rate, weight and density increasing the flexibility in producing casting. Green wax (for silicon gel investment casting) and yellow wax (for sodium silicate investment casting) are a few examples of waxes used in this process.

- The net shape can be manufactured as dependency on the heavy gating system is very low.

- The secondary machining process is deficient as the flexibility to produce cavities in casting and manufacture high dimensional tolerance casting with high-quality casting surface is possible as compared to sand casting because of die and ceramic moulds used.

- Secondary machining operations such as polishing and trimming are eliminated in this process.

- Casting components do not have any parting line and flash. The flash defect is non-existent here as compared to the die-casting process.

- Best for producing components for small sizes with a high production rate as repeatability is possible.

- This is a draftless casting process, This process does not require a draft. A straight 90°degree angle component can be produced.

- Higher surface finish products are possibly better than sand casting, squeeze casting, slush casting and die casting.

- Fine details are possible to produce because of the use of ceramic mould and wax expendable patterns.

- Material which is difficult to machine on lathe and milling machines such as cast iron, carbon steel, magnesium, heat resistance steel and stainless steel can be shaped and formed to desirable customer requirements reducing the machining cost of the final casting.

- Multiple patterns can be made from the metal die and branched-out mass-producing casting using a common runner during the casting process.

- The wax pattern is a more economical pattern material having high flexibility for producing integrated shape components.

- This process is more economical for producing complex shape casting in small batches than the die-casting process.

- Shrinkage allowance and machining allowance given on the wax pattern are minimum for producing casting.

- High control over grain size, grain orientation, shape and distance between them is possible to control the production of high-quality dense casting products.

- Assembly of wax patterns are not required to produce the final casting saving time. The entire tree pattern can be dipped in the ceramic slurry with any special assembly practice.

Investment Casting Disadvantages

- Ceramic and plaster moulds need to be broken and produced for every casting.

- Skilled labour is required for the job of producing master patterns, die and assembling wax pattern clusters.

- The process is a labour-intensive process that requires monitoring from producing the master die to break out the final casting from the ceramic slurry mould.

- Longer lead time, larger production cycle and time-consuming methods as this process has more steps to produce casting from raw material to the final casting as compared to the die casting process.

- Limitations over casting size and dimensions as larger casting cannot be obtained that we manufacture through the dry sand casting process.

- Casting having multiple recesses, cavities, holes and inserts is difficult to produce with this method.

- Producing small quantity investment casting is expensive as the special tooling cost for manufacturing master dies, wax patterns, ceramic mould and inspection tools used in this process are costly.

- The weight of the casting to be manufactured is mostly limited to 10 kg to produce precise casting, as pattern tree assembly becomes heavy due to self-weight and it becomes difficult to control the process parameters of the casting process.

Investment Casting Application

- New product development prototype sample products.

- Steam turbine blades, gas turbine blades, Kaplan turbines and components.

- Golf club heads and gimbal components.

- Gold, silver precious jewellery, religious idols and ornaments.

- Art, decoration, sculptures, statues, lamb base and candle stands.

- Individual spur gears in gearboxes, pedestrian units, cams and followers, connecting rods and pistons of the compressor, gas tanks, chain links and sprockets, clutch parts and gear shift levers.

- Centrifugal pump casting, nozzle ring (axial and radial), pump connectors and piston, lobe pump bearing and rotor outer housing and cases.

- Studs, sockets, ratchets, flanges and gaskets.

- Medical equipment and supplies

- Hydraulic and pneumatic cylinders.

- Pump components. diffusers, pipe and valve fittings such as nozzle, needle valves, gate valves, pressure realize valves, ball valves, steam valves, butterfly valves, diary valves and valve bodies.

- Dental tooth, crowns and caps.

- Heat exchanger, heat sinks, cooling components and heating flame nozzles.

- Fasteners such as nuts and bolts.

- Machine tools parts and hand tools.

- Marine and defence industry.

- Satellite, radars, robotic and land rover components.

- Ship anchors, propeller blades, shaft bushes and boat cleats.

- Landing gear components, aircraft engines, jet engines and engine blocks.

- Pulleys, plough parts, agriculture machine components and large hammers.

- Parts of alternators and power generators.

- Door locking system, vessels, utensils, pipe clamps and fire water hydrant hydraulic parts.

- Logos, emblems and small marks can be cast on any casting components.

- Transmitter housing, turbocharger rotors and covers.

- Material handing parts of converges.

- Micro-spur gears and open/close micro-impellers of turbochargers are a few applications produced by vacuum investment casting.

- Energy, gas, machinery, packaging, petroleum, oil industries, pneumatic industry, material handling equipment, food industry, mining, electrical, diary industry, renewable energy sector, electronic, construction, farming, aircraft and aerospace industries.

Investment Casting Conclusion And Summary

Precision investment casting dates back thousands of years ago in China, Egypt and Mesopotamia where beeswax were used to produce patterns to manufacture final casting products.

Early investment casting only had aesthetic value for producing jewellery, sculptures, art pieces and ornaments but soon the potential of manufacturing casting components having engineering value with good mechanical properties made this process popular in engineering commercial sectors.

This is an efficient process that has more flexibility than any other casting process to produce complex casting in a short lead time to customers.

New investment casting processes such as the water glass investment casting method have been invented in China which uses water glass as the binding agent for producing moulding shells as the process is less complicated.

New 3D printers are now used in this process to produce more versatile intricate castings at a lower manufacturing cost per piece by printing shells and patterns directly.

Modern techniques such as CAD/CAM, casting stimulation, selective laser sintering, material jetting, binder jetting, additive manufacturing, subtractive manufacturing, rapid prototyping and fused deposition modelling are used to manufacture pattern-reducing production cycle steps for highly accurate casting in shorter time.

Finishing operations such as antique coating, painting, chrome plating, corrosive resistance coating, mirror polishing, galvanizing and pickling can be easily performed on these casting products produced from the lost wax casting process.